From Nuisance to Necessity — The Problem with Flex

Flex banners—ubiquitous across our cities—are often seen fluttering from poles or stacked in piles after an event ends. Made from polyvinyl chloride (PVC), flex is durable, cost-effective… and almost entirely non-biodegradable.

What’s worse? Disposing of it ethically is difficult, and recycling options are limited. Most discarded banners end up in landfills, choking rivers, or get burned—adding toxins to the air.

But what if this environmental hazard could be reimagined as a resource?

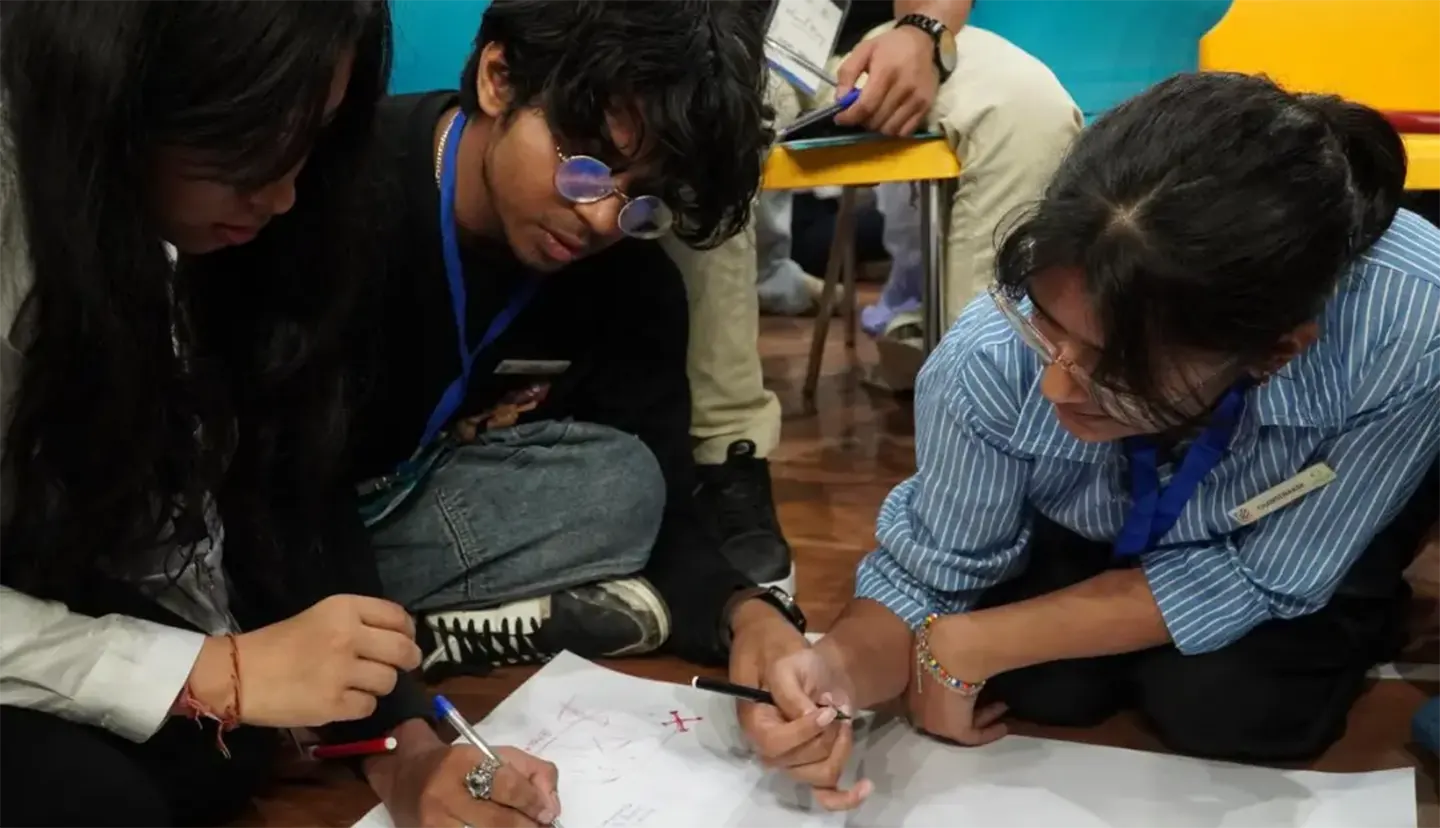

Innovation Rooted in Need

In 2013, Goonj received a large roll of used flex banners. While most would have seen it as a burden, we saw an opportunity.

That year, in Gangori (Uttarkashi, Uttarakhand), the leaky roof of a village school was temporarily fixed using flex. Not only did it protect the children through monsoon, it lasted an entire year—proving durability and utility in the harshest conditions.

Since then, flex has journeyed through villages and flood-hit areas as a practical, low-cost solution—covering tin shanties, creating dry flooring in relief centers, and shielding stored materials from moisture.

Flex sheets used as roofing during monsoons in Uttarkashi

Stitching Circularity into Daily Life

At Goonj’s Delhi workshop, Reena, a long-time team member from the Green by Goonj initiative, shares

“We once used to buy buckram to stiffen our cloth bags and wallets. One day, I tried using flex instead—and it worked beautifully.”

From that moment, flex became a staple input in Green by Goonj’s upcycled product line—giving it a second life as linings in wallets, school bags, and folders.

In Bihar, at Cloth For Work enabled stitching centres built after the 2008 floods, flex was used for roofing and walls. These centres later became livelihood hubs for over 750 women who were trained and eventually started micro-enterprises.

Empowering Menstrual Dignity, One Pouch at a Time

In remote areas, many women who use Goonj’s MY Pads (cloth sanitary pads) struggle with one overlooked challenge—where to store used pads until they can be washed.

Flex stepped in again.

Goonj began repurposing small flex scraps into leak-proof, washable pouches—added to the MY Pad kits. For women working long hours in fields or construction, this small innovation brought not just ease, but privacy and dignity.

Flex-based pouch included in Goonj′s MY Pad kit

Circular Thinking Meets Grassroots Wisdom

From flood-prone villages to urban workshops, from school roofs to menstrual hygiene kits—flex found its way into the lives of the vulnerable.

This story isn’t just about recycling. It’s about:

Turning an unused product into a dignity-focused design

Blending grassroots innovation with environmental stewardship

Recognising that sustainability isn’t a luxury—it’s often born of necessity

Final Thought

Flex may not be the ideal material. But until better alternatives become accessible and scalable, we choose to turn this “necessary evil” into a tool for resilience, restoration, and reuse.

As always, we listen to the gaps—and flex with them.

Be a Part of Change

Our invitation to you is, start from where you are.. From a small change of starting a Goonj kee Gullak or Team 5000, joining a long and deep change process, or things in between- organising a collection drive, a volunteering journey, an internship, or simply walking with us signing for a Goonj monthly newsletter subscription.. More on www.goonj.org or write to [email protected].

Many options, but the choice is always one; Taking Action..